How To Prevent Underground Dump Truck Tip Overs

Common Causes of Underground Dump Truck Tip Overs

Uneven Road Conditions in Underground Mines

Underground mines are rough and tricky places. Roads there often have steep hills, tight curves, and slippery or loose ground. These make underground dump trucks likely to tip over. When a truck climbs a slope or hits bumpy ground, its balance can shift fast, especially if the load isn’t spread evenly. A small mistake in speed or steering can cause big trouble.

Overloading and Improper Load Distribution

Putting too much weight in an underground dump truck is a common problem. Extra material, especially if it’s piled unevenly, lifts the truck’s center of gravity. This makes tipping more likely. For example, a fully loaded UK-20 weighs 40,500 kg, with 18,400 kg on the front axle and 22,100 kg on the rear axle, which can keep the vehicle balanced to the maximum extent possible.

Operator Error and Lack of Training

Even the most advanced machinery cannot compensate for human error. Inexperienced operators may misjudge turning radii, fail to recognize unstable terrain, or improperly manage speed during dumping operations. Without proper training and experience, even minor mistakes can lead to accidents.

Poor Visibility and Restricted Maneuvering Space

Underground tunnels are tight and dim. Drivers struggle to see far or spot dangers ahead. The small space limits how much they can move, raising the chance of hitting walls or other gear. Both can cause underground dump trucks to tip.

Design Features That Improve Stability in Underground Haul Trucks

Low Center of Gravity Chassis Design

A low center of gravity keeps trucks balanced. The UK-6, built for tight spaces (2.5 m x 2.5 m), has a side-seated driver’s spot. This boosts both sight and steadiness when moving forward or backward.

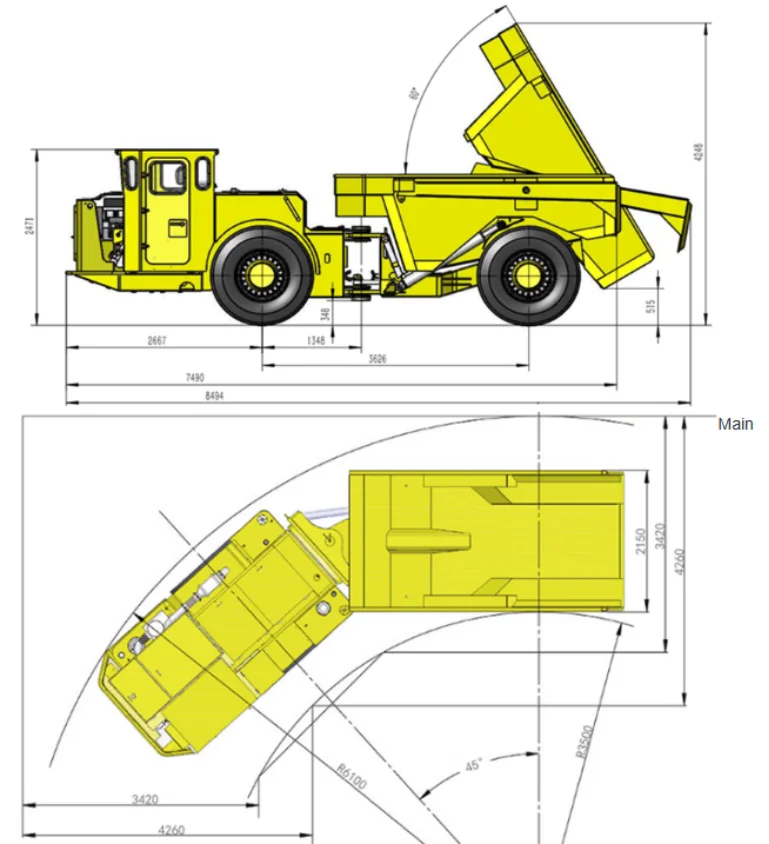

Articulated Steering Systems for Tight Spaces

Flexible steering helps underground haul trucks handle sharp turns safely. The UK-12 has an articulated frame with a turning radius of 4585 / 7135 mm and a 40° turn angle. It’s perfect for small-to-medium underground jobs where space is scarce.

Enhanced Suspension Systems for Rugged Terrain

Strong suspension soaks up bumps from rough ground. It cuts down shakes that could tip the truck. The UK-15 uses stiff planetary axles with front axles that tilt (±8°). This keeps wheels glued to uneven surfaces.

The Role of Maintenance in Preventing Tip Overs

Regular Inspection of Tires, Brakes, and Suspension Components

Checking parts often keeps underground dump trucks safe. Worn tires slip easily. Bad brakes slow stopping. Weak suspension makes the truck wobble. All these can lead to tip overs.

Monitoring Hydraulic Systems for Stability Control

Hydraulic systems run key tasks like lifting the dump box or steering. A failure can cause wild moves or loss of balance when dumping. Regular checks spot leaks or weak pressure early.

Training and Certification for Underground Haul Truck Operators

Structured Operator Training Programs by Qixia Dali Mining Machinery Co., Ltd.

We provide clear training plans for our machines. These teach safe driving in real mine settings. Our trainers focus on how underground haul trucks work, their limits, and spotting dangers in tight spaces.

Simulation-Based Learning for Hazard Awareness

Simulators mimic underground mines. Drivers practice sharp turns, heavy loads on slopes, and emergency moves safely. This builds skills without real risks.

Ongoing Skills Assessment and Refresher Courses

Machines change, so drivers must keep up. Regular tests ensure they can use new tools like automatic alarms or self-lock systems on trucks like the UK-15.

Equipment Customization Options from Qixia Dali Mining Machinery Co., Ltd.

Tailored Design Solutions for Specific Mining Environments

Every mine is different. Some need small underground dump trucks for narrow paths. Others want big haulers for heavy jobs. We adjust sizes, engines, and safety features for models like UK-6, UK-12, and UK-20.

Load Monitoring Systems to Prevent Overloading in Underground Dump Trucks

Stopping overloads starts with knowing limits. Our trucks have smart systems that warn drivers when loads are too heavy. This eases strain on axles and cuts tip-over risks.

Advanced Safety Features Integrated into Underground Haul Trucks

Our trucks are equipped with advanced safety features to ensure maximum protection for drivers. Rear-view cameras provide clear visibility when reversing, while reverse alarms alert operators of potential hazards behind them.

Additionally, auto-warning systems for oil temperature, pressure, and electrical issues help keep drivers informed about the truck’s condition, preventing accidents and enhancing overall safety.

Site Management Strategies to Minimize Risk of Tip Overs

Designing Stable Haul Routes Within the Mine Layout

Good planning lowers risks before trucks move. Engineers should create routes with smooth curves, steady slopes, good drainage, and enough width. This makes safer paths from loading to dumping zones.

Implementing Traffic Control Measures in Confined Areas

Crowded mines raise crash risks. Sudden turns or stops in a loaded underground dump truck are dangerous. Signs, clear lanes, right-of-way rules, and radios keep traffic smooth.

Coordinating Load Distribution Across Multiple Underground Dump Trucks

Smart teamwork prevents overloading one truck while others carry less. Even loads reduce wear on trucks, keep sites productive, and boost safety.

Frequently Asked Questions (FAQ)

What are common causes behind underground dump truck tip overs?

Tip overs happen due to rough mine roads, overloading or uneven loads, driver mistakes from poor training, and dim, tight tunnels.

How does articulated steering improve safety?

Flexible steering lets trucks like the UK-12 turn tight corners without leaning too much. Its bendy frame keeps balance with good turn angles.

Why is regular hydraulic system maintenance important?

Hydraulic issues during dumping or steering can cause wild moves that tip trucks. Checks stop problems before they grow.

What type of training do operators receive?

Drivers get clear programs with simulator practice for spotting dangers in tight spaces. Refresher courses from Qixia Dali Mining Machinery Co., Ltd. keep skills sharp.

What features make Qixia Dali’s UK-series trucks safer?

Our UK-series has ISO ROPS/FOPS cabins, SAHR brakes, rear-view cameras, reverse alarms, and auto-lock systems. These make underground haul trucks safer.

To learn more about how our gear can make your mine safer and more productive, reach out to us at Qixia Dali Mining Machinery Co., Ltd. We started in 1998 in Yantai City. Our factory spans 130,000 square meters. We have over 200 workers, including 90 technicians and engineers. We focus on designing, building, installing, and training for underground mine gear, ore processing tools, spare parts, and sales.

About Us

Qixia Dali Mining Machinery Co., Ltd was established in 1998, located in Yantai City.

The company is mainly engaged in the design, development, production, installation and training of underground mine equipment and ore processing equipment, spare parts supply and sales.

MoreContact Us

- Xinbang Rd, Private Economy Park, Qixia, Shandong Province, China

- +86 135 5307 3459

- ytdali@ytdali.com

+86 13553073459

+86 13553073459

+86 13553073459

+86 13553073459